Our solutions saved 50 million m3 water!!!

Systainable expert solutions dramatically improve the performance of textile factories in terms of efficiency, cost and sustainability. Since 2010 our customers have saved stunning 50,000,000 m3 fresh water and reduced greenhouse gas emissions by more than 1.3 million tons CO2. Thus Systainable Solutions contribute tangibly to increased sustainability of the textile processing industry.

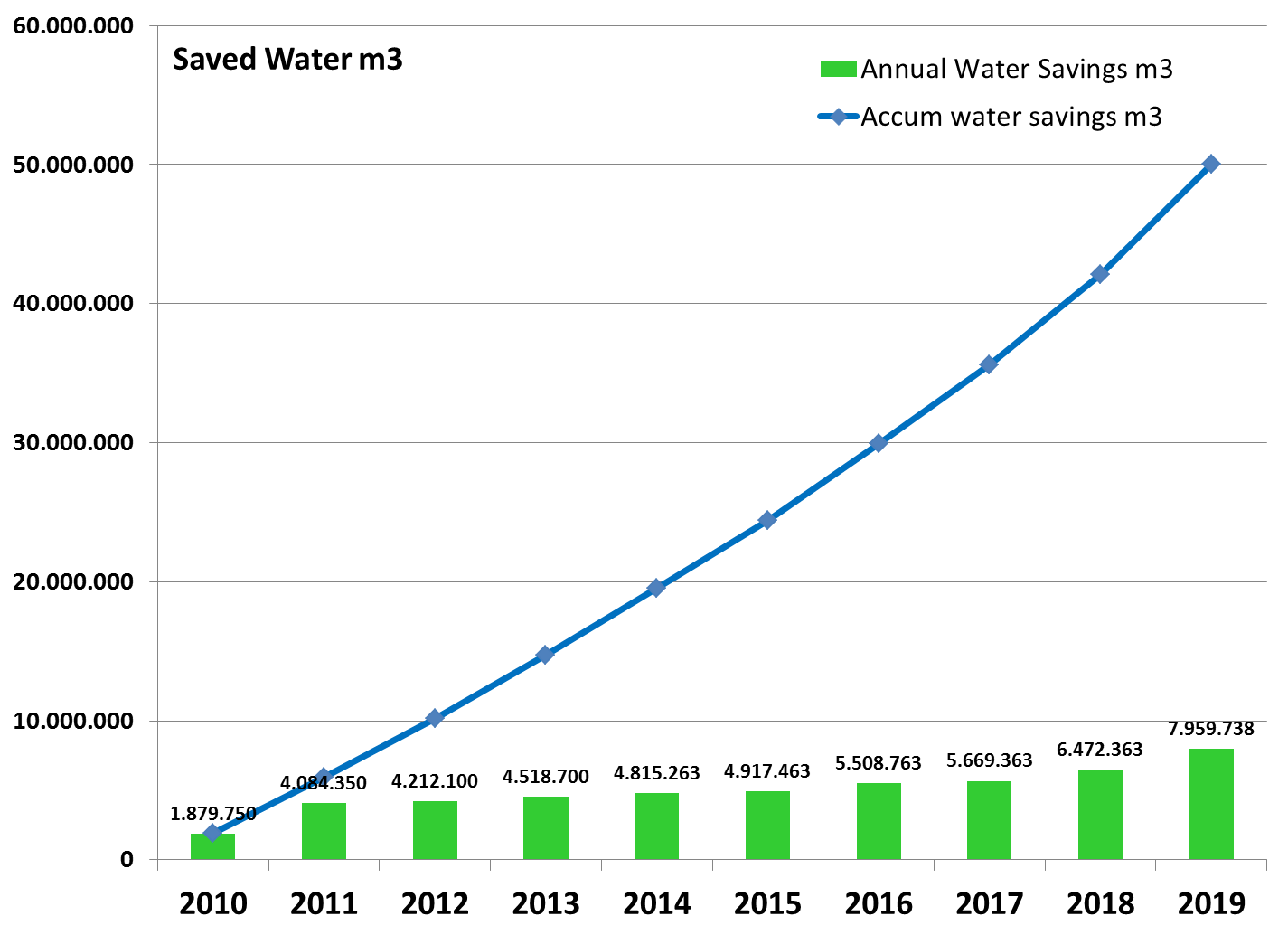

The chart depicts realized water saving (annual and accumulated):

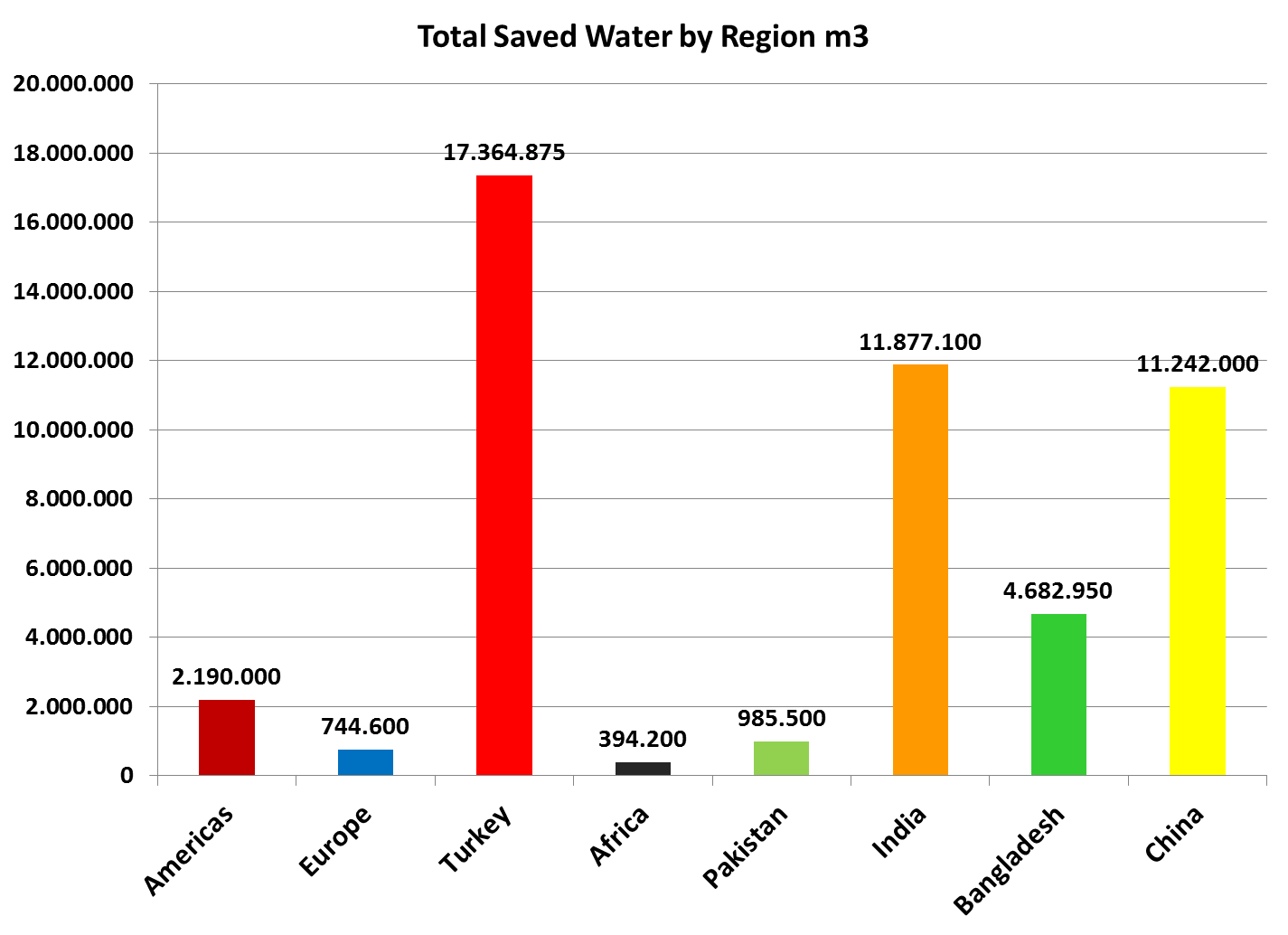

Broken-down by region achieved water savings amount to:

The savings of 50 million m3 water and 1.3 million t CO2 were achieved while processing a total of 1.3 million tons fabric; the average savings are 38l water and 1kg CO2 per kg of fabric. Furthermore roughly 350 million kWh electricity and 4,000,000 tons steam were saved (equivalent to 500,000 tons coal). At the same time proportional, substantial savings in chemicals and waste water has also been realized. The resulting average cost saving per kg of fabric is roughly 0.1-0.2$/kg of fabric, i.e. the total achieved cost savings for our customers are between 130-260 million US$.

Putting figures into perspective

- 500,000 t coal equal 25,000 truckloads!

- 50 million m3 water cover the daily fresh water needs of 5 billion people (www.who.int)

- 1.3 million t CO2 equal the emissions of 3,300 flights Beijing-London (or the CO2 absorbed by 650 million trees – 26,000 sq km of mature forest (100 trees per 4,000sqm)- in 1 year!!)

- 1.3 million t fabric are required to produce 3 billion t-shirts!!!

- Total cost saving: anywhere between 130-260 million US$ (no need to explain!)

The stunning figures underline the benefit that can be achieved through optimizing and fine tuning textiles processing by means of the comparatively low cost, quick-win Systainable SystainSuite expert systems.